In mid-1946 engineer Ian Duncan moved to North Walsham, ostensibly to build canning machinery for his brother, Albert Duncan, who had set up Duncan Canning on Norwich Road.

Once established in town, Ian Duncan set about his intention to build his own car (or buggy, as he called it), and, gathering a team around him, he took over his brother’s Park Hall on New Road to form Duncan Industries (Engineers) Ltd. The first job was to organise a machine shop. The premises were in a poor state and needed considerable attention but, as David Rogerson, the works manager recalls, the worst job was to dispose of several tons of curry which had gone off!

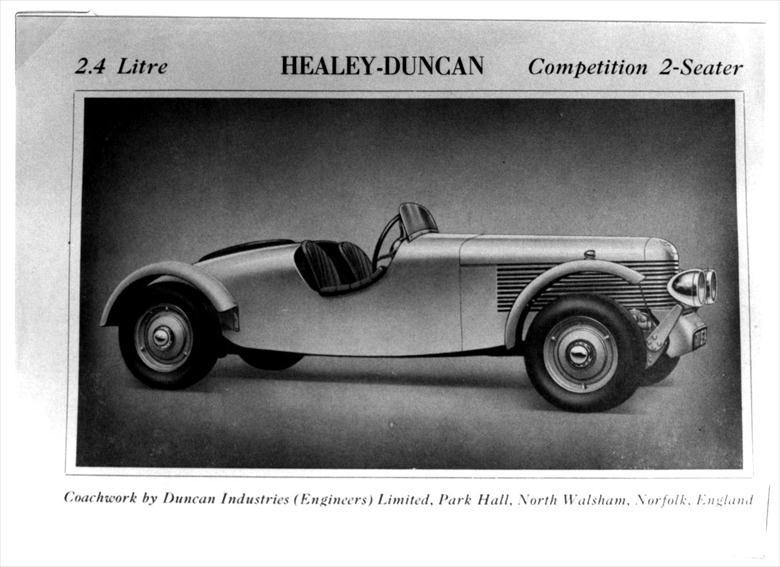

The Duncan Healey

Duncan Industries first used Healey chassis in the summer of 1947 and fitted the modified bodies of a Hillman Minx (see photo), a Ford Anglia and a Ford Prefect to them. Then, in October 1947, a grey-green Healey Duncan was wheeled out of Park Hall. This was an elegant vehicle with looks ahead of its time. ready to take its place on the Healey stand of the Paris Motor Show where it became the world’s fastest production sports car with a speed of 104 mph.

However the Paris Show car was a near disaster. The firm’s one and only painter had left in a hurry and David Rogerson and Freddie Mears, who had joined the team from Rover, rubbed down the bodywork time after time as the cellulose refused to take. Eventually Mr.Wally Hannant, of Hannant’s Garage, was called in to complete the spray job with hours to spare.

But worse was to come! The car had been splendidly upholstered by Cook & Hastings, Norwich. Mr. Rogerson reported that when he sat in the car the upholstery split from end to end. It was hurriedly repaired and the car sent to Paris with bars across the doors to prevent enthusiastic viewers entering and repeating the damage.

The Association of Healey Owners believes that some 39 saloons and 3 coupes were built on a Healey chassis.

The Duncan Alvis

In 1946 both Healey and Alvis were producing more chassis that they could use and this led to Duncan Industries building bodies for them. The success of the prototypes using bodies of the Hillman Minx, Ford Anglia and Ford Prefect so impressed the Alvis agents at the Reliance Garage in Norwich that their Sales manager, Stan Bosher, asked Duncan to body-up an Alvis Fourteen Chassis.

Designed by Frank Hamblin, it was coach-built and each frame took three weeks to make, on a jig with 62 pieces of laminated ash screwed and glued with Aerolite 300F, the resin used to hold the wooden Mosquito aircraft together. Before Duncan Industries became self-sufficient, the early frames were made by boat builders Graham Bunn of Wroxham and Herbert Woods of Potter Heigham. With their body building capabilities progressing, Duncan Industries soon outgrew the Park Hall premises and, in the autumn of 1947, took over one of the old hangars and other outbuildings at the old RAF Swannington, and transported the 140 strong work force daily, by bus.

Alas, the success was short lived. Duncan Industries fell victim to punishing purchase tax rules. Each car cost about £2,200 and about a third of that was tax (to encourage the government’s post-war export drive). A short-lived solution was the Duncan Drone, a skimpy body on a Healey chassis which would sell for a shade under £1,000, and so avoid the high level of tax. Of course, at this price the passenger seat, windscreen and spare wheel were all extras!

The Alvis Owners Club believe that 30 Duncan Alvis cars were made, of which about 15 survive.

The Duncan Dragonfly

Whilst building the Duncan Healey, Duncan Alvis and Duncan Drone, work progressed in secret for Ian to produce the first mini car. The principal designers were Alan Lamburn (who had previously worked on the Fleet Air Arms Barracuda aircraft) and Frank Hamblin (who had helped develop a heat exchanger for the Gloster Meteor, Britain’s first operational jet. Both had considerable pre-war experience in the motor industry and the team’s efforts resulted in the Duncan Dragonfly.

Ian Duncan with Duncan Healey (back) and Duncan Dragonfly (front) in 1948

The summer of 1948 saw the light blue prototype become a familiar sight on the roads around North Walsham and Norwich as Ian Duncan was anxious to cover as many miles as possible so that any shortcomings in the design would soon become apparent.

In 1948 the company went into receivership and the Dragonfly was sold to Austin to help settle debts. North Walsham’s claim to fame in the motor industry finished at the end of 1948 and the town lost a very talented team of engineers.

Ten years later, in August 1959, Austin introduced another transverse-engined, front wheel drive car with rubber suspension, the same constant velocity joints and the same ten inch wheels as the Dragonfly. That was the hugely successful Austin Mini. Was it inspired by the earlier Duncan vehicle ? we will never know.