Manufacturing

Randells was founded by Frank Randell in the 1820s, with an ironmongery shop in North Walsham, and a foundry at Northrepps. As this was before the railway reached Norfolk, pig iron and coke were delivered by wherry to North Walsham and transported on by horse and cart to Northrepps. The opening of the Gas Works in North Walsham in 1838 supplied coke locally, but still delivery by horse and cart. The railway did not reach North Walsham until 1874, nearly 10 years after the move to the town.

An 1897 report on the estates of Frank Randell describes warehouses, workshops, stabling and two cottages on Grammar School Road. Part of that site is now occupied by the Cat Pottery and originally included Tinmans and Whitesmiths shops.

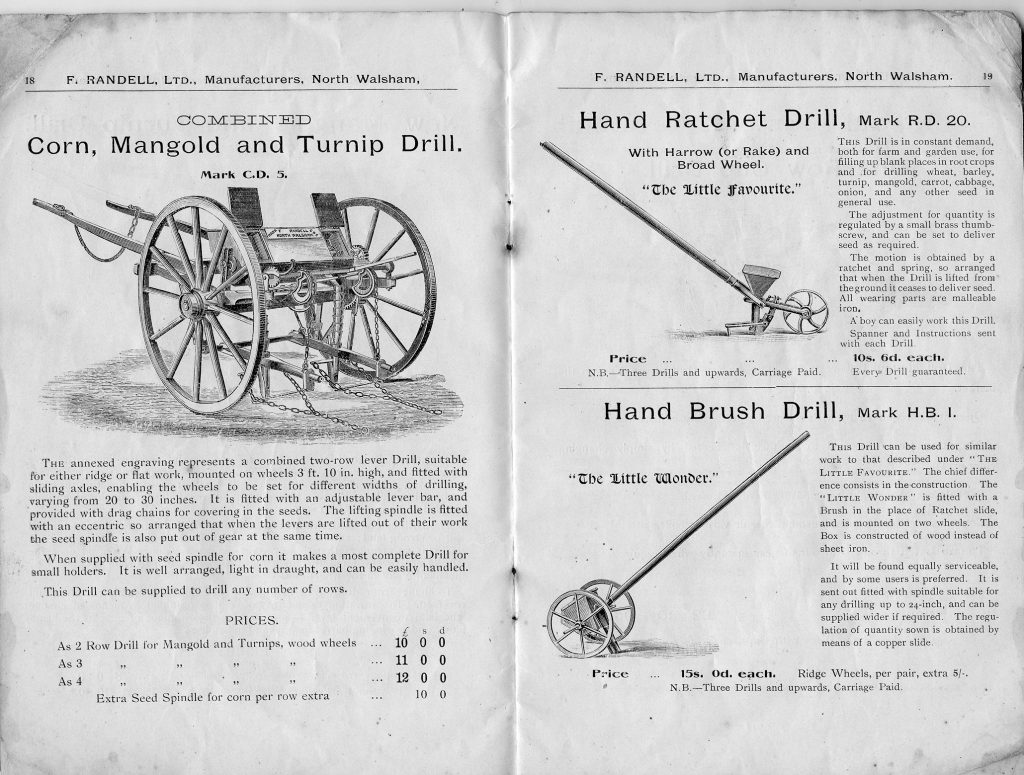

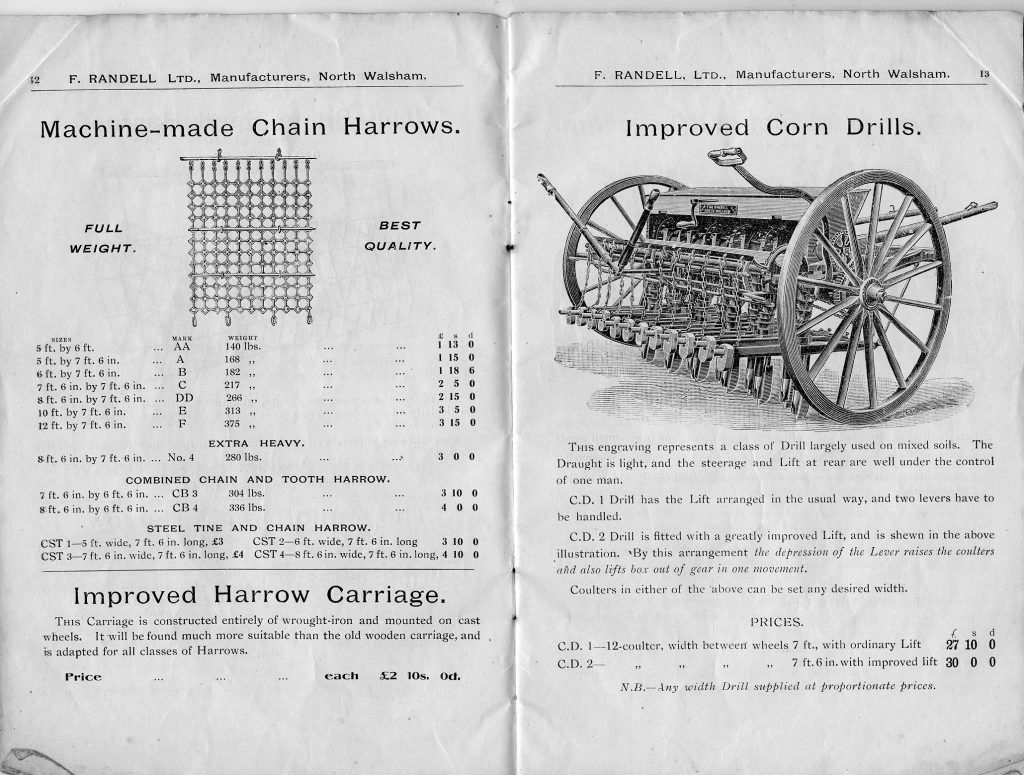

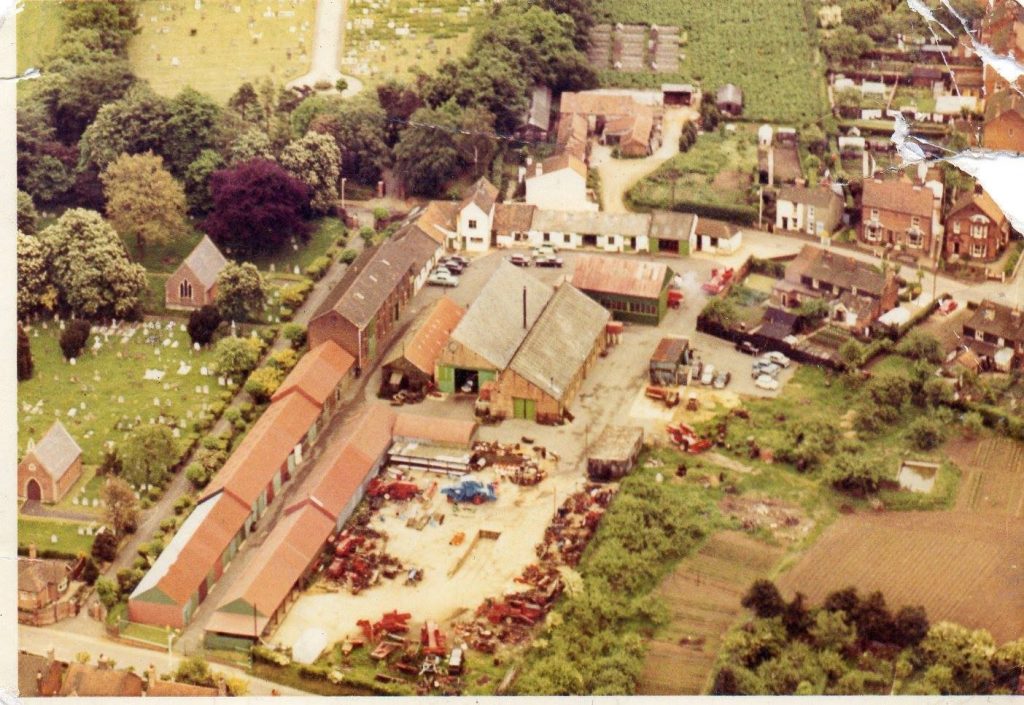

The St Nicholas Works, named after the nearby church, was a site of over 3 acres. At its busiest there were 20 buildings, including the foundry, pattern makers/carpenter’s shop and no less than 6 blacksmith’s shops! Until the 1950’s, most of the products were horse drawn, there was an extensive woodwork facility to produce the shafts. The machine shop had a selection of machine tools driven by belts from overhead shafts originally powered by a gas engine. There was also a tinsmith’s shop in Grammar School Road on the site now occupied by the Cat Pottery.

In addition to manufacture, the works had always operated as a repair workshop, both for its own products and those of other manufacturers, for example, Ransomes Ploughs. The most significant move, however, came in the 1930’s when Randells took on the agency for the Canadian based Massey-Harris company, who produced binders, mowers, reapers and eventually combine harvesters.

As well as manufacturing, there were other operations: Ironmongery, from the earliest days, culminating in the market place shop in 1897; a sizeable electrical contracting department; and from 1931 another agricultural engineering business in Reepham.

During the 1939-1945 war, the firm didn’t undertake military manufacture, however the drive to become self-sufficient in food produced a lot of repair work. Although most of the skilled workers were classed as in ‘reserved occupations’, some of these were taken to work on munitions at Boulton & Paul in Norwich.

However, with the emphasis now on acting as selling and servicing agents, the end of manufacture was in sight. The foundry, which latterly cast on Friday afternoons, ceased operations in 1955. Castings required for such products as landrolls were then bought in.

Manufacture ceased totally in the late 1950’s, but selling, servicing and electrical contracting continued to flourish.

In 1963, Dalgetty Franklin Ltd acquired the assets of F.Randell Ltd. and traded as F.Randell & Co. under the management of Geoffrey Bloom. The business closed in the 1980s and, in 1990, the St Nicholas Works was demolished in preparation for the new Somerfield Supermarket which has since changed to Sainsbury’s.

The Randell family

Frank Randell had four sons and they each specialised in different aspects of the business.

- Frank Victor Randell ran the ironmongery side in North Walsham and Cromer and, on his death in 1954, was succeeded by his son Michael.

- John Randell took care of the agricultural side and greatly expanded the tractor and combine harvester part of the business (in the 1950s they were selling 100 combines a year), which necessitated the phasing out of the manufacturing activity.

- Fred Randell managed the electrical engineering business and converted numerous country houses and public halls to electricity.

- In 1931, the Company acquired a similar agricultural engineering and ironmongering business in Reepham and William Randell, the 4th son, took over the management.

On his retirement in 1963 he was succeeded by his son Reginald, who had developed a very sought-after skill and numerous speedway motorcycles, from several countries, made their way to Reepham to receive the expert tuning that only he could give.